One-stop Logistics Solution Integrator

JK Robotics

Three Roads to Make Smart Logistics Come True

System Development

System Concepting

System Engineering

Parameter Analysis

Layout Design

Modeling & Simulation

Solutions

This is What Tomorrow Looks Like

JKR Vision

고객에게 시스템을 통합할 수 있는 다양한 솔루션을 제공해서 더욱 스마트하고 효율적인 물류환경이 되도록 합니다.

To provide clients the wide range of solution to integrate their systems and make their logictics environments smarter and more efficient

JKR Mission

고객이 높은 수준의 경제적 가치를 창출할 수 있도록 지원하여 함께 각 산업에서 탁월함의 새로운 표준을 설정합니다.

To help our clients create such high levels of economic value that together we set new standards of excellence in our respective industries

JKR Value

모든 것을 자동화하거나 완벽한 답을 얻는 것에 대해 걱정하지 마십시오. 일단 시작하기, JKR이 추구하는 가치입니다.

Don’t worry about automating everything or having the perfect answer. Start simple! This is the true value JK Robotics pursues.

JKR Slogan

Our best is your best!

Business Partner

최고 기술력을 보유한 전문가들과의 Partnership, Smart Logistics구현을 위한 최상의 Teamwork

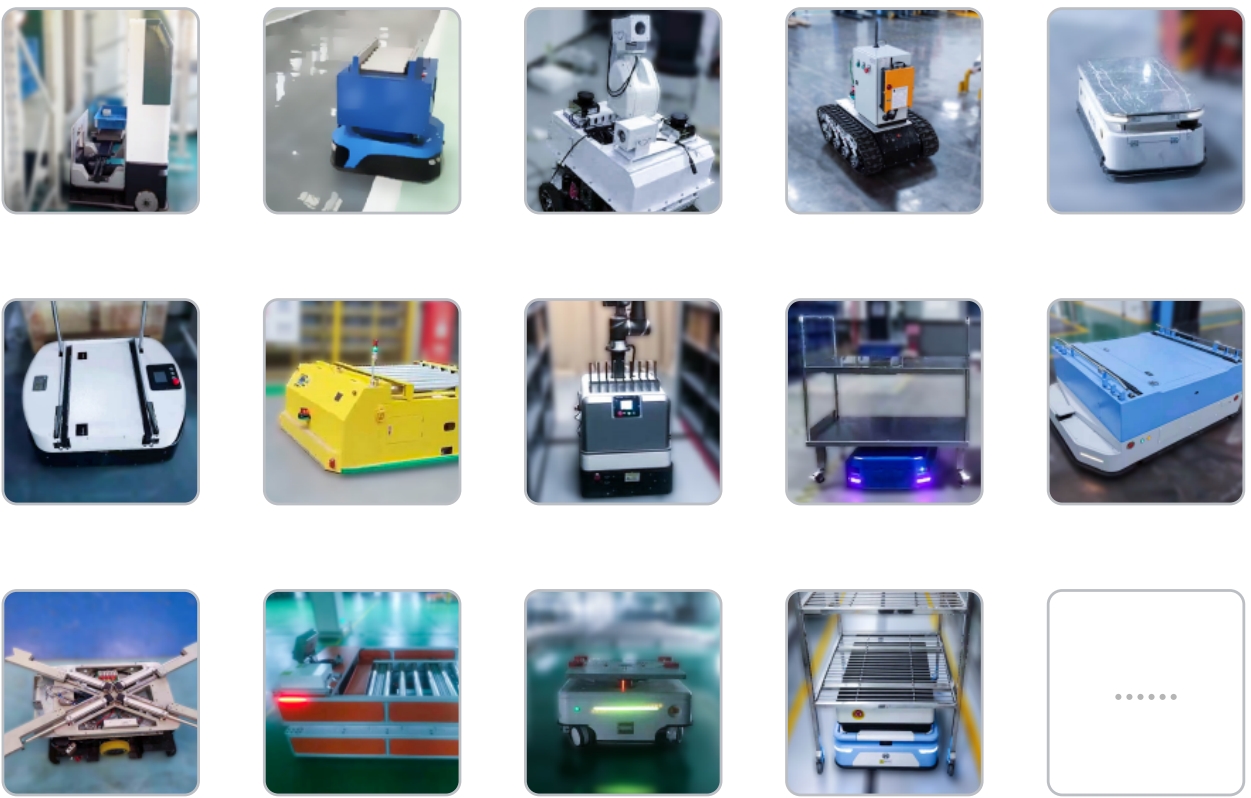

Autonomous Mobile Robot Solutions

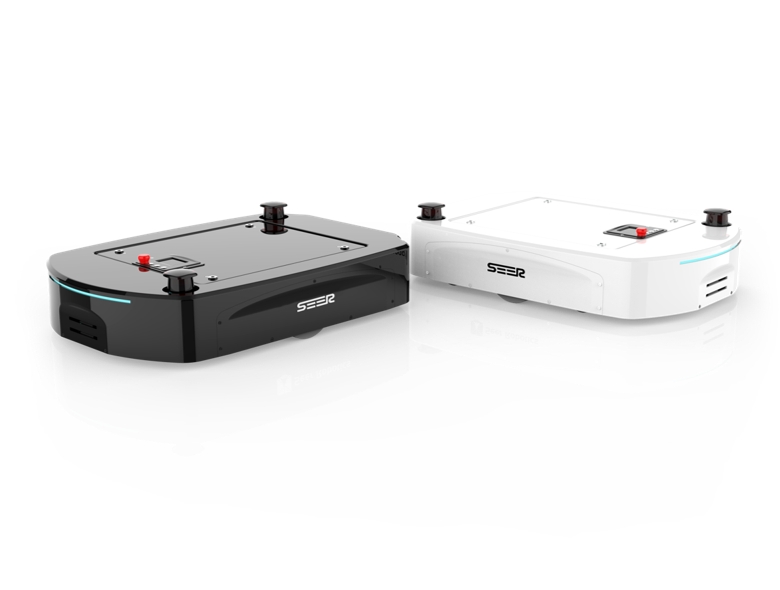

Standardized Auto Mobile Bases

The AMB (Auto Mobile Base) series products are standard AMR chassis

equipped with laser SLAM technology

AMB시리즈는

레이저슬램 기술을 장착한 표준 AMR 섀시입니다.

AMB-150 / 150D

Laser SLAM

Load Capa.: 150kg

Speed: Max.1.4m/sec

Accuracy: +-5mm

Battery Life: 12hr

AMB-300 / 300D

Laser SLAM

Load Capa.: 300kg

Speed: Max.1.4m/sec

Accuracy: +-5mm

Battery Life: 12hr

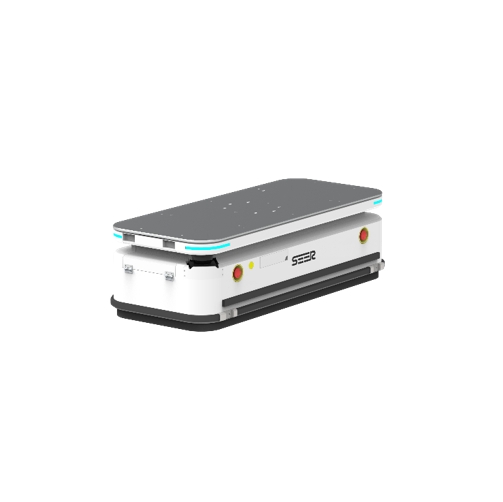

AMB-300XS (ISO Class 4)

Laser SLAM

Load Capa.: 300kg

Speed: Max.1.5m/sec

Accuracy: +-5mm

Battery Life: 8hr

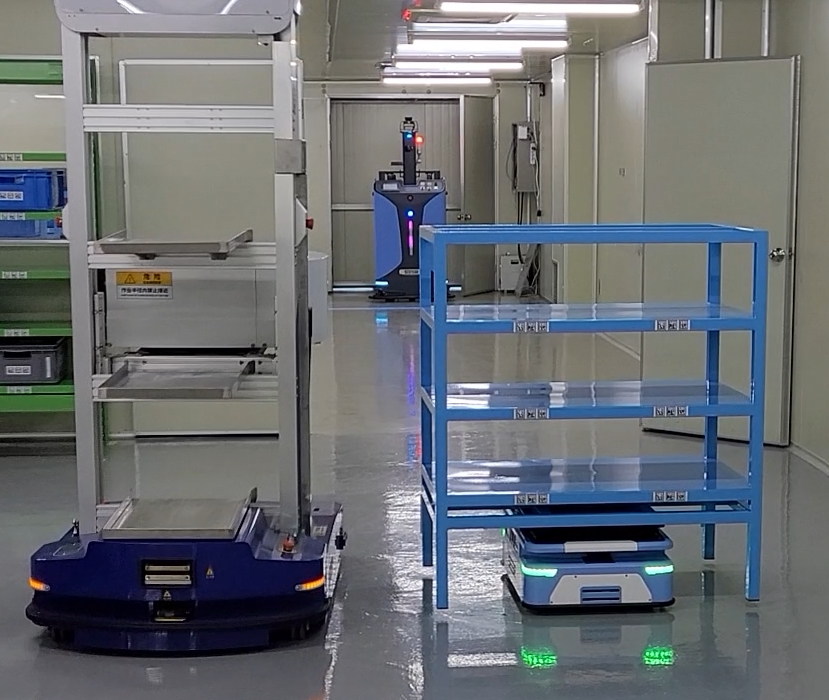

AMB - Applications

AMB + 적재함

Laser SLAM (LiDAR: 1 or 2)

Based upon AMB-150

Suitable for loading at work station

Standardized Jacking Robot

AMB-J and SJV series products are standard jacking robots equipped

with cutting-edge laser SLAM technology.

Jacking 전용 AMB-J 및 SJV 제품은

최첨단의 레이저슬램 기술을 장착한 표준 Jacking Robot입니다.

AMB-150J

Laser SLAM

Load Capa.: 150kg

Speed: Max.1.5m/sec

Accuracy: +-5mm

Battery Life: 8hr

SJV-SW500

Laser SLAM

Load Capa.: 500kg

Speed: Max.1.67m/sec

Accuracy: +-5mm

Battery Life: 10hr

AMB-800K

Laser SLAM

Load Capa.: 800kg

Speed: Max.1.8m/sec

Accuracy: +-5mm

Battery Life: 8hr

SJV-W1000

Laser SLAM

Load Capa.: 1,000kg

Speed: Max.1.67m/sec

Accuracy: +-5mm

Battery Life: 6hr

SJV-W600DS-DL

Laser SLAM

Load Capa.: 600kg

Speed: Max.1.2m/sec

Accuracy: +-5mm

Battery Life: 8hr

Multi-Purpose Picking Robot

SPK Picking series products with laser SLAM technology are

multifunctional products that can be applied to various fields.

레이저 슬램 기반의 Picking Robot은

공정간 물류 뿐만 아니라 신속한 다품종 처리를 요하는

창고물류에

최적화된 제품입니다.

SPK-HAI-A42-3

Laser SLAM

Load Capa.: 30kg/Box * 3

Speed: Max.1.3m/sec

Accuracy: +-10mm

Battery Life: 6hr

SPK-HAI-A42-5

Laser SLAM

Load Capa.: 30kg/Box * 5

Speed: Max.1.3m/sec

Accuracy: +-10mm

Battery Life: 6hr

SPK-HAI-A42-7

Laser SLAM

Load Capa.: 30kg/Box * 7

Speed: Max.1.3m/sec

Accuracy: +-5mm

Battery Life: 6hr

Powerful Forklift Robot

SRC-powered laser SLAM forklift robot supporting customization to

provide powerful solutions for the moving of pallets, material cages,

and racks

팔레트/자재함 이송, 적재, 분류작업의 생산성과 안전성 향상을 위한

최고의 물류로봇입니다.

SFL-CBD15

Laser SLAM

Load: Max. 1,500kg

Travel Speed: Max.2.0m/sec

Lifting Height: 120mm

Accuracy: +-10mm

SFL-CDD14 (CE)

Laser SLAM

Load: Max. 1,400kg

Travel Speed: Max.1.5m/sec

Max. Lifting Height: 1,600mm

Accuracy: +-10mm

SFL-CDD16

Laser SLAM

Load Capa.: 1,600kg

Travel Speed: Max.2.0m/sec

Max. Lifting Height: 3,000mm

Accuracy: +-10mm

SFL-CPD15-T

Laser SLAM

Load Capa.: 1,500kg

Travel Speed: Max.1.5m/sec

Stadnard Lifting Height: 3,300mm

Accuracy: +-10mm

Auto Charger

Rapid and low-level noise charging pile

충전 컨트롤러가 탑재된 저소음, 고속 자동충전기입니다.

SCS-1500

AMB / Jacking Robot

Input voltage: 220VAC

DC output: 48V

Max. output current: 15A

Max. output power: 900W

SCS-3501

Picking Robot

Input voltage: 220VAC

DC output: 48V

Max. output current: 30A

Max. output power: 1,800W

SCS-C24100D

SFL-CDD14 외

Input voltage: 220VAC

DC output: 24V

Max. output current: 100A

Max. output power: 3,000W

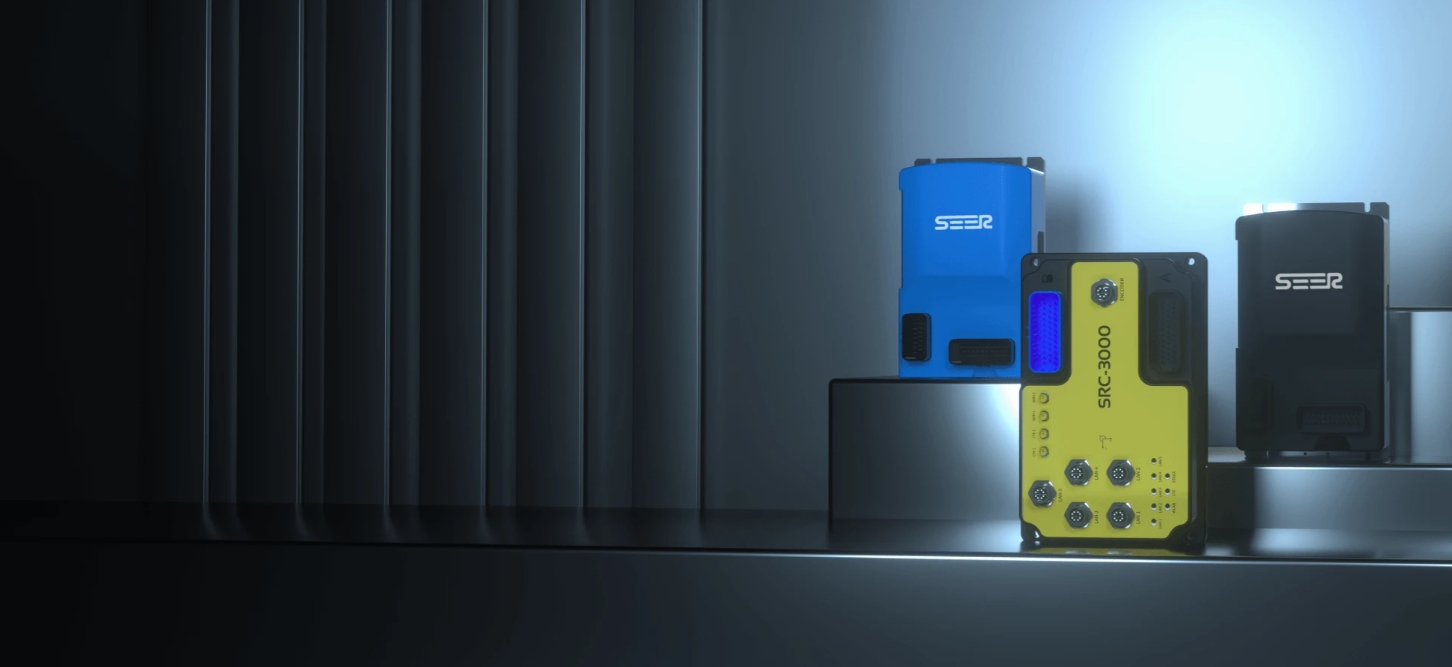

Mobile Robot Controllers

SRC Core Controllers

Enable easy building of high-performance mobile robots

SRC Core Controller는

로봇의 모든 작업을 제어하는 고성능 컨트롤러입니다.

SRC-2000-I(S)

AMB, Jacking, Picking Robots

Interface: Ethernet / Wifi(2.4G, 5G)

Nav. Speed: Max.2m/sec

Accuracy: +-10mm

Certificate: CE (CE-EMC)

SRC-2000-F(S)

Forklift Robots

Interface: Ethernet / Wifi(2.4G, 5G)

Nav. Speed: Max.2m/sec

Accuracy: +-10mm

Certificate: CE (CE-EMC)

SRC-3000FS

For Safety Requirement

Perform. Level: ISO13849-1 Cat.3 PLd

OP. Temp.: -30℃~ 50℃

IP Grade: IP65

Interface: Ethernet / Wifi (2.4G, 5G)

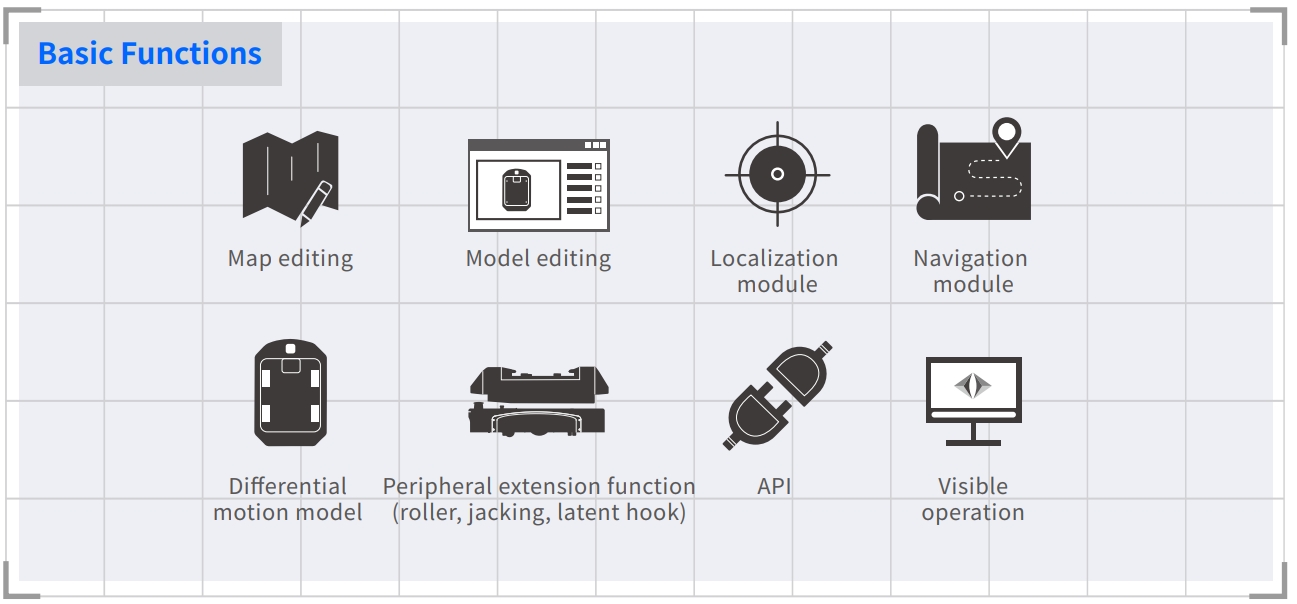

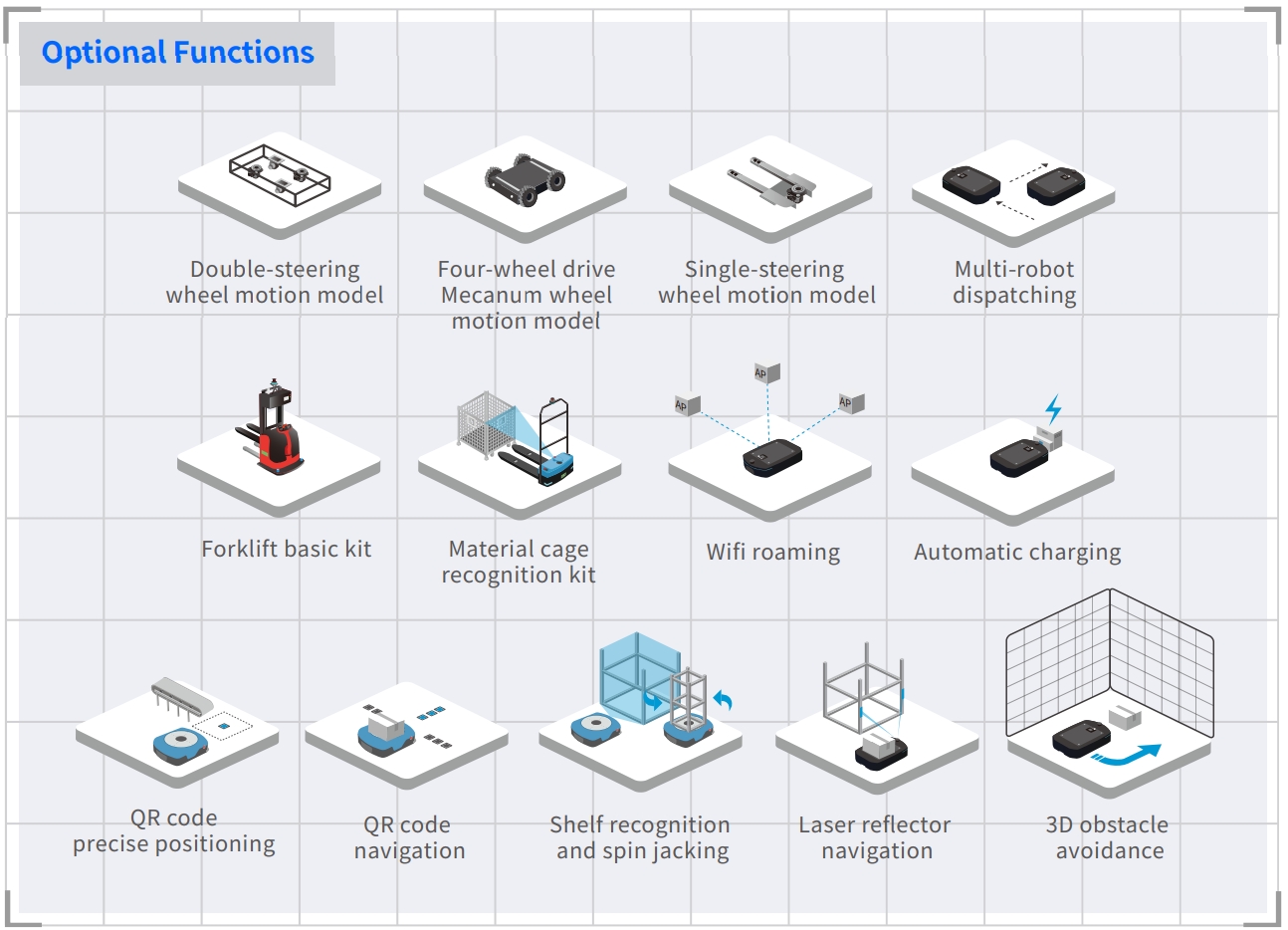

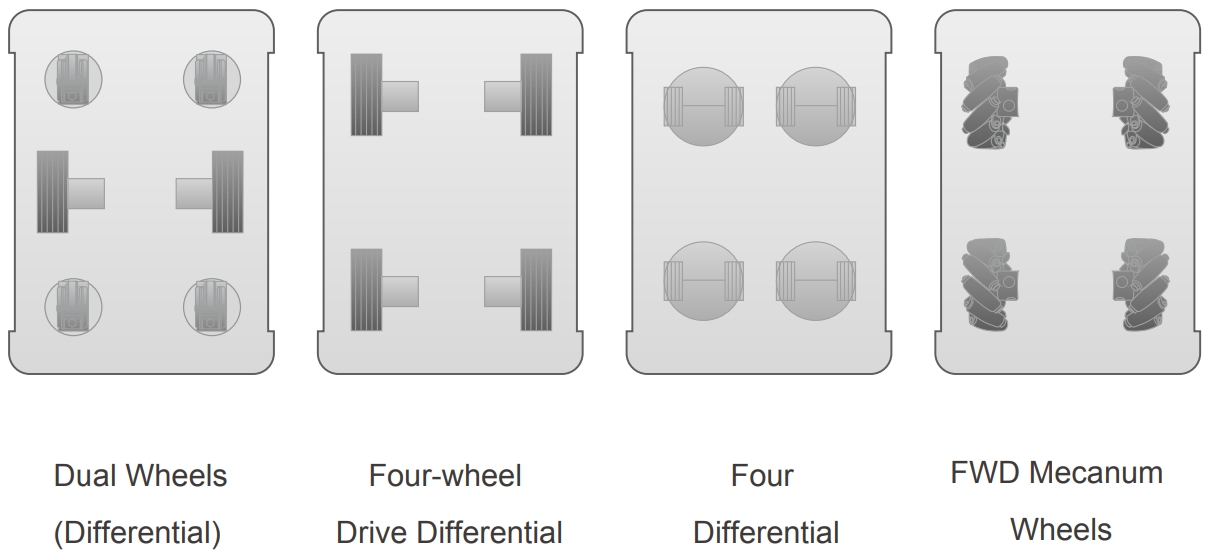

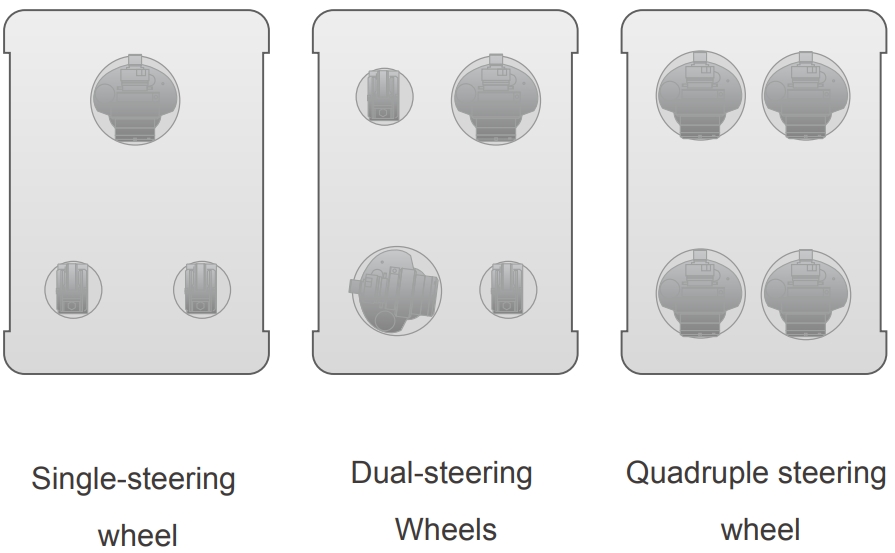

Comprehensive Functions, Easier to Built Robots

종합적이고 최적의 기본 기능과 풍부하고 실용적인 옵션 기능이 결합되어 고객이 One-stop으로 현장에서 Mobile Robot 운용이 가능하도록 지원합니다.

Standardized S/W and H/W Configurations

Robokit S/W 및 H/W를 사용하여 SRC 원스톱 구현 소프트웨어(Roboshop Pro)를 통해 다양한 모션 모델과 장애물 회피기동, 팔레트 인식 등 현장의 니즈에 최적화된 AMR솔루션을 제공합니다.

Ultra-Adaptability + Major Brand Compatibility

분야별 최고의 하드웨어와 호환이 가능하여 고객 선택의 폭을 다양하게 할 수 있습니다.

Large Model Variety for Complex Operation Requirement

SRC Core Controller는 복잡한 Workshop 환경과 요구사항을 완벽하게 구현할 수 있는 다양한 유형의 AMR Customizing Application을 제공합니다.

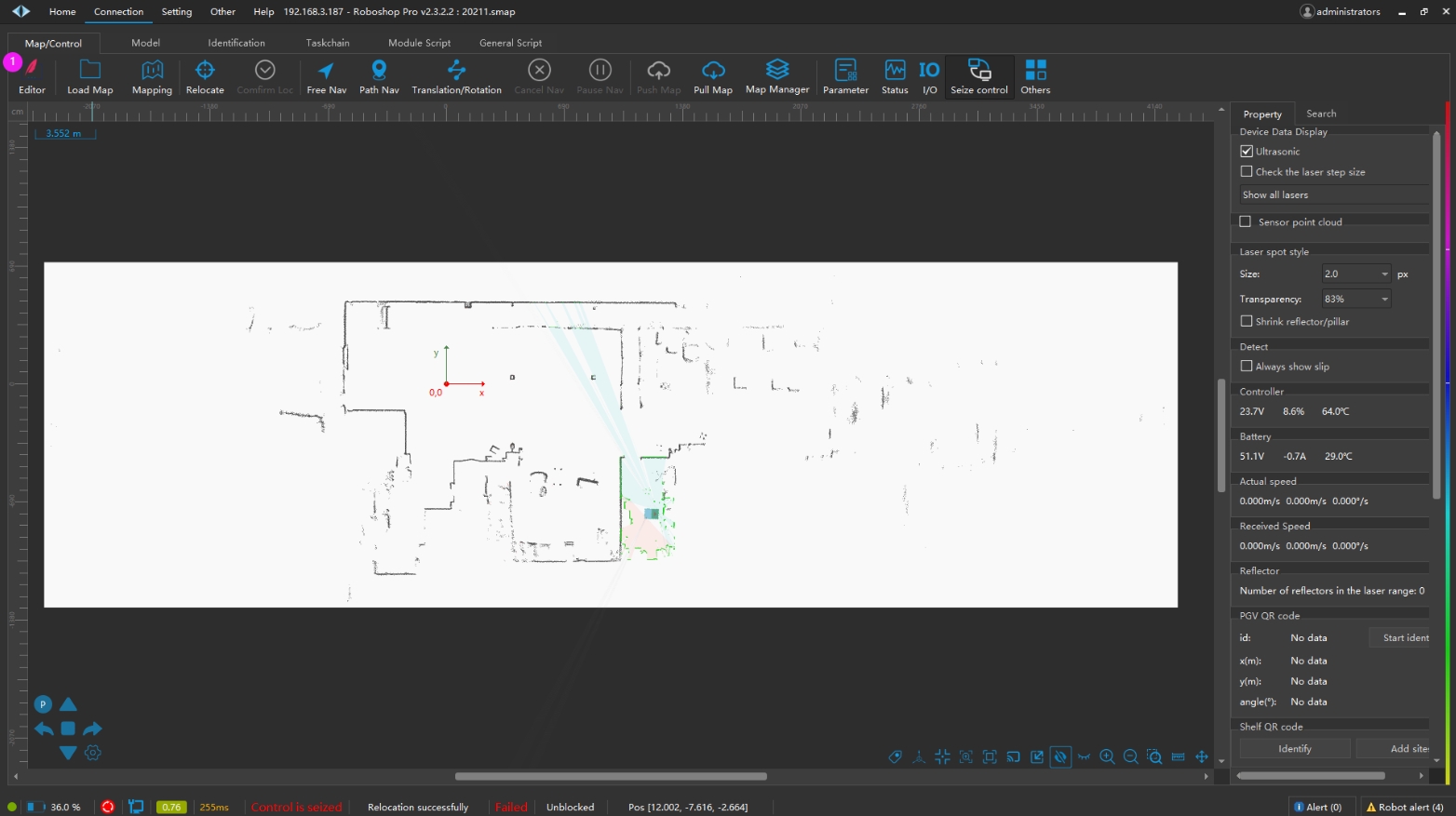

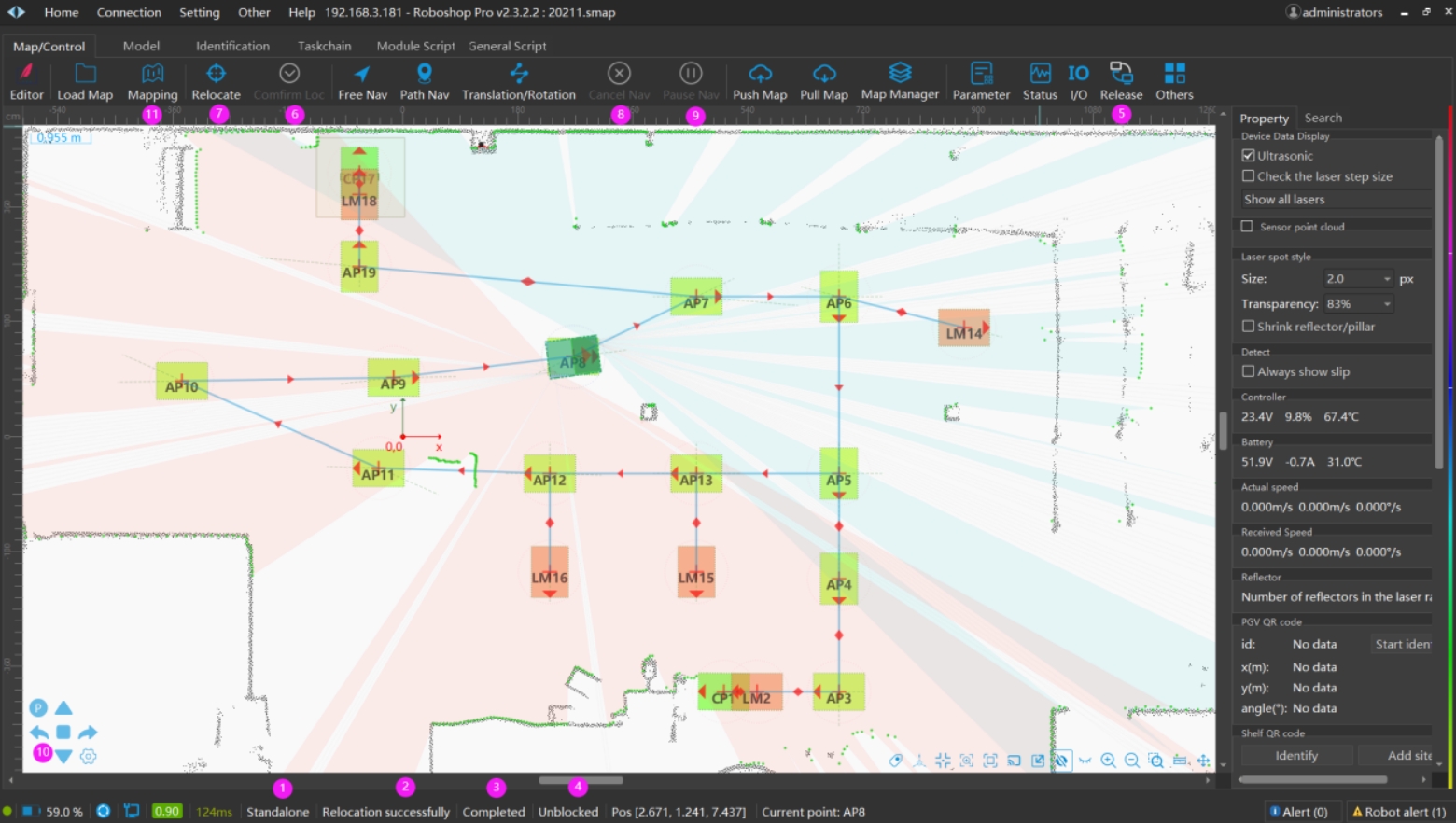

Mobile Robot Software

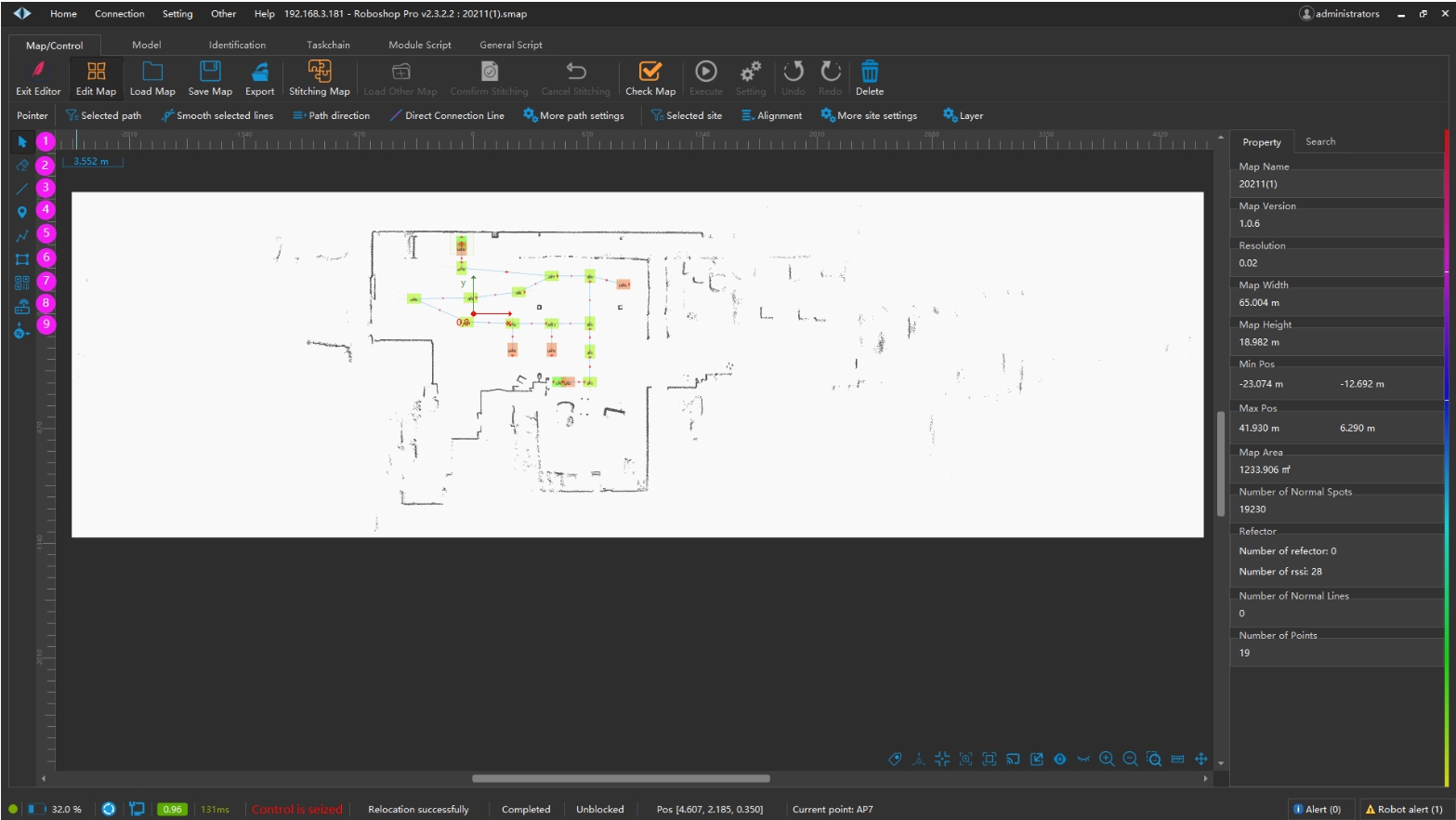

One-Stop Implementation Tool - Roboshop Pro

The visual guided robot building makes it easy to build mobile

robots.

The entire process is visualized from the creation of a model to the

editing of the model.

Roboshop Pro는 지도작성(mapping), 위치추정(localization), 지도편집(map

editing)

작업 명령(work process and order) 및 로봇 제어를 위한

모든 파라미터 설정 기능을

제공하는

Robot Control Software입니다.

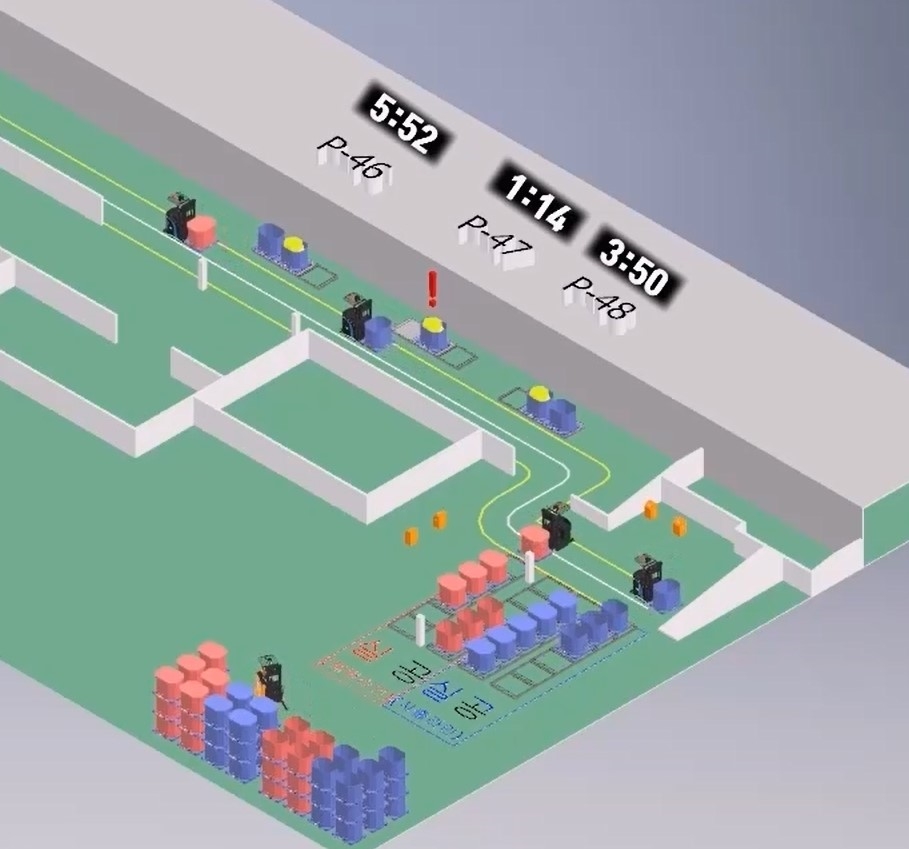

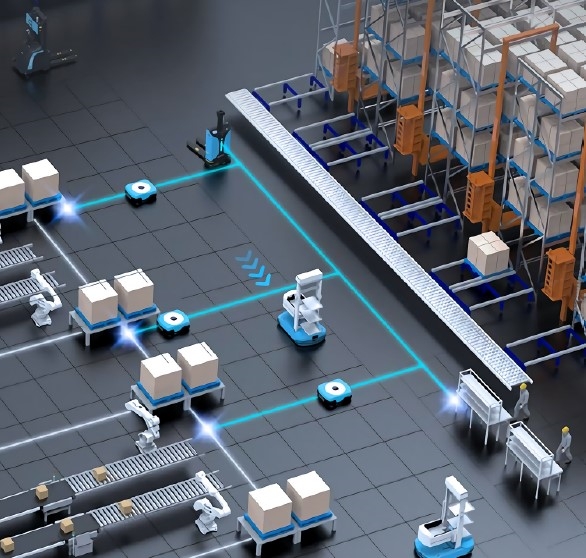

Robot Dispatching System - RDS

New generation of dispatching system for the unified management of

mobile robots and factory automation logistics

로봇 배치 및 관제 기능을 담당하는 RDS는 물류 지능화 구현을 위한 핵심

소프트웨어입니다.

전문적인 프로그래밍 지식이 없어도 시스템 구축이 가능한 Low Code

Solution이며, 100여대 이상의

로봇 및 장비 관제를 하나의 RDS로

운용할 수 있는

Smart Logistics 구축을 위한 필요충분 소프트웨어입니다.

✚ 제품보관 위치에 대한 시실시간 모니터링 및 작업지시

✚ 워크샵에 운용중인 로봇과 기타 장비(엘리비이터, 자동문 등)에 대한 Traffic Control

✚ 운용중인 로봇의 상태 모니터링 및 알람 표시

✚ 다양한 로봇을 활용한 콜라보

Smart Warehouse Integration Solution

3D 4Way Shuttle System

New generation pallet storage system with high density, flexibility

and scalability

JKR이 제공하는 3D 4Way Shuttle System은 기존의 Mother Car/Baby

Shuttle의 이원화 구성이 아닌

안정적이고 안전한 고속의 단일 Shuttle System

선입선출 대응이 가능할 뿐만 아니라 일반 AS/RS에 비해

30%이상 높은 보관효율로 투자비용을 최소화할 수 있습니다.

3D 4Way

Shuttle System은 Laser SLAM AMR과 통합 운영이 가능한 혁신적인 4세대

창고설비입니다.

Pallet Shuttle

3D 4Way

Laser SLAM AMR과 통합운영

Installation Height: Max. 25m

Load Weight: Max.1,500kg

Travel Speed: Max.1.5m/sec

Mini Shuttle

Single/Double Deep

Laser SLAM AMR과 통합운영

Installation Height: Max.6.5m

Travel Speed: Max.4m/sec

Automated Retrieval & Storage System (AS/RS)

Providing super dense inventory storage to maximize floor space.

JKR이 제공하는 자동창고시스템은

첨단 로봇기술과 AI기술을 자동화창고에 접목하여 공간활용을 극대화하고 운영 비용을 획기적으로 절감합니다.

특히, Laser SLAM AMR을 자동창고와 통합 운영하여 진정한 Smart

물류 구축이 가능합니다.

Pallet AS/RS

Pallet

Laser SLAM AMR과 통합운영

Installation Height: 40m

Travel Speed: Max.120m/min

Mini Load AS/RS

Tote

Laser SLAM AMR과 통합운영

Installation Height: 20m

Travel Speed: Max.300m/min

Automated Truck Loading System

This special loader saves space and time in the loading and unloading area.

무인자동화에 대한 니즈는 물류의 시작점부터 출발합니다.

JKR이 공급하는 Truck Loading System은 물류의 출발선을 더욱 안전하고

공간을 절약하며 전체 운영비용을 절감하는 최적의 설비입니다.

Picking Spider System (PSS)

New Generation Material Handling

PSS는 고밀도 지능형 Bin-to-Person 솔루션입니다.

JKR이 공급하는 PSS설비는 여러 큐브와 여러 로봇으로 구성되어 성능과 용량을 더욱 높일 수 있습니다.

높이와 채널 공간을 최대한 활용할 수 있으며, 저장밀도는 기존 창고의 6배 이상 입니다.

Space Utilization

Shelves: Max.8.3 bins/m2

PSS: Max.52.2 bnis/m2

공간활용도

약 6.2배 증가

Seamless Interface

PSS + AMR/AGV

PSS + Conveyor

PSS + Robot arm

Operation Efficiency

Carrying Moving Speed: 3m/s

Picking Time: 15s

30kg per PSB

Productivity: 60bins/hr

Roulette Sorter

New Species for Sorting

Intelligent Roulette Sorter

룰렛소터는 루프형 방식(크로스벨트, 틸트트레이) 및 직선형 방식(슬라이드슈) 등 통상적인 분류설비의 개념을 완전히 뒤바꾼 혁신적인 솔루션

원형의 섀시부와 분류부로 이루어진 견고한 2단 구조로, 인덕션(투입구)의 수량에 따라 분류효율을 높을 수 있습니다.

특히 JKR과 Megvii의 창의적인 AI기술이 집약되어 99.99%의 높은 분류성능으로 오구분의 가능성을 현격히 줄여 비용을 최소화하고 효율성을 극대화할 수 있는 Smart Sorting System입니다.

Advantages

High Efficiency

Saving Space

High Sorting Accuracy

Reducing Missorting

Perfomance

Sorting Efficiency: 4,600p/h

(Single Zone)

Double Zone: 9,200p/h

Sorting Accuracy: 99.99%

What's New

2022로보월드

2022.10.26.~29까지 일산 킨텍스에서 개최된 '2022로보월드'에 Laser SLAM 자율주행로봇과 3D Pallet Shuttle System을 출품하여

많은 호응과 관심을 받았습니다. 전시회 기간 동안 저희 부스를 방문하여 주신 모든 분들께 감사 말씀을 드립니다.

또한, 2023.4.18~21까지 킨텍스에서 개최되는 '2023 KOREA MAT'에도 출품예정이며, 더욱 향상된 시스템 성능을 확인할 수 있습니다.

2023 Smart Factory

2023.03.08.~ 10.까지 코엑스에서 개최된 '2023 스마트팩토리 및 자동화산업전'에 협력파트너인 CJ올리브네트웍스의 요청으로 Laser SLAM 자율주행로봇과 24V-Powered Soreter/Diverter를 출품하여 뜨거운 반응을 얻었습니다. 특히, 자율주행로봇과 컨베이어 시스템의 매끈한 협업을 통한 거의 완벽한'무인화'에 부스 방문객들의 관심이 집중되었습니다.

Korea MAT 2023

JK로보틱스는 2023.04.18.~ 21.까지 일산 킨텍스 제1전시장에서 개최된 'Korea MAT 2023 국제물류산업대전'에 다양한 Laser SLAM 자율주행로봇과 3D 4Way Pallet Shuttle System, 그리고 24V-Powered Soreter/Diverter를 출품하여 자율주행로봇과 자동창고시스템을 하나의 시스템으로 통합한 One-Stop Solution을 선보였습니다. 저희 부스를 방문해 주신 모든 분들께 감사드리며, 더욱 혁신적이고 강력한 통합 솔루션 제공으로 보답하겠습니다.

Contact Us

Copyright © 2023 JK Robotics Co., Ltd. All rights reserved.